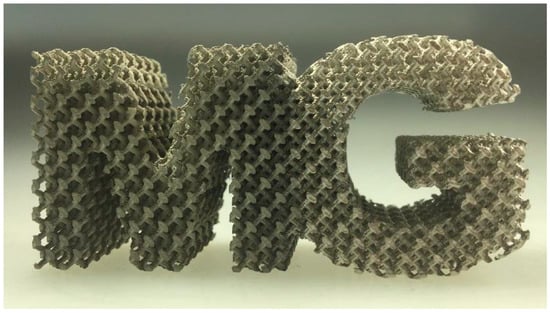

Additive Manufacturing with Magnesium and Aluminum

Dive into the future of manufacturing with our expertise in additive manufacturing. We specialize in utilizing magnesium and aluminum alloys to create high-performance components with complex geometries. Our state-of-the-art technology ensures precision and efficiency, making us your partner of choice in pushing the boundaries of what's possible.

Material Selection and Optimization

Benefit from our in-depth knowledge of magnesium and aluminum alloys. We carefully select and optimize materials based on your specific application needs, considering factors such as strength, corrosion resistance, and thermal properties. This ensures that the final product meets the highest standards of quality and performance.

Prototyping and Rapid Iteration

Accelerate your product development cycle with our rapid prototyping services. Additive manufacturing allows for quick design iteration and validation, reducing time to market. Experience the agility of our processes as we transform your concepts into tangible prototypes with efficiency and precision.

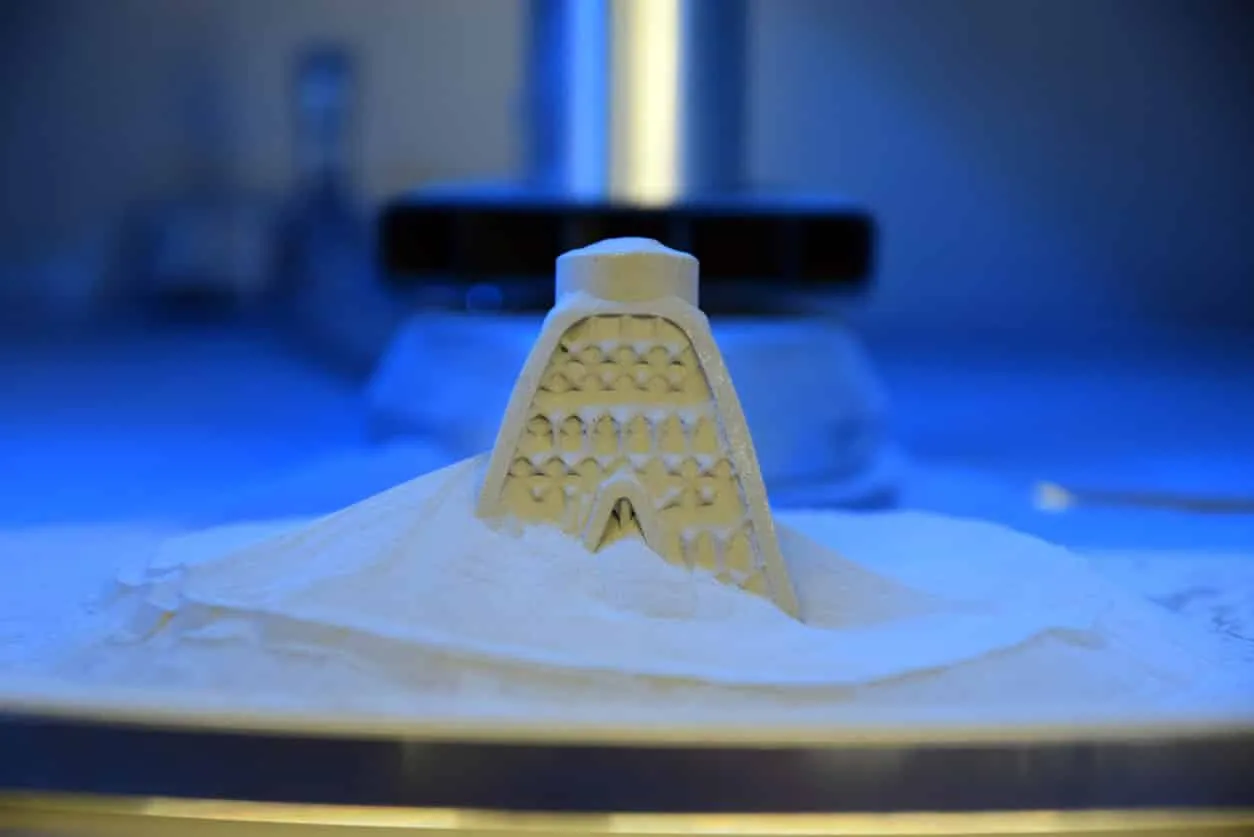

State-of-the-Art Additive Manufacturing Technologies

Leverage our cutting-edge additive manufacturing technologies, including selective laser melting (SLM) and electron beam melting (EBM). Our state-of-the-art equipment ensures consistent and repeatable results, setting the stage for the production of precise and high-quality magnesium and aluminum components.

Quality Assurance

Trust in the reliability of our services with our stringent quality assurance measures. From material handling and powder characterization to post-processing and inspection, we adhere to industry standards and best practices. Your satisfaction is our priority, and we guarantee parts of the highest quality and accuracy.